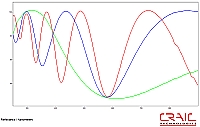

Typical test spectra from for thin film thickness

Industries that use film thickness measurements include:

- Optics

- Semiconductor

- Films on stents

- and much more....

Small spot thin film thickness measurement can be done both by transmission and reflectance..

Thin film thickness measurement is done to monitor the thickness of thin films for a number of reasons. These include such diverse industries as semiconductor integrated circuit manufacturing, anti-reflective coatings on optics, protective coatings and many more. In all of these cases, it is critical to have consistent thickness of the films that are being deposited on the surface. This can be done by acquiring the transmission or reflectance spectrum of a microscopically small area and calculating the thickness of the film. This can be done for many locations on the item to map the changes in film thickness across the surface.

The CRAIC Technologies™ microspectrophotometer tools allow for non-destructive and non-contact thin film thickness measurement of sub-micron sized areas in both reflectance and transmittance. CRAIC instruments can also measure polarization anisotropy, optical emissions and even fluorescence. These flexible tools are equally at home in the R&D laboratory, the fab floor or the failure analysis facility. Currently, CRAIC solutions are used for film thickness measurement of semiconductors, LCD displays, OLED's, and optical products.

To learn more about thin film thickness measurement and how microspectrophotometers do it, select one of the following links:

Thin Film Thickness Measurement Science